Manufacturing Motorcycle Spare Parts High Precision Sprocket by Powder Metallurgy

Shijiazhuang Jingshi New Material Science and Technology Co., Ltd.- After-sales Service:1year

- Warranty:1year

- Type:Engine Parts

- Material:Iron

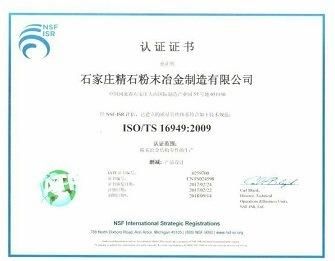

- Certification:ISO,Ts16949

- Number of Row:Double Row

Base Info

- Surface Treatment:Oil Impregnant

- Density:7.0g,cm3;-7.4G,Cm3;

- Tensile Strength:1100MPa

- Yield Strength:430MPa

- Transport Package:PE Bag, Bubble Bag, Carton, Pallet

- Specification:Suited size carton

- Trademark:HLXCL

- Origin:China

- HS Code:8409999100

- Production Capacity:600000,Year

Description

Basic Info.

Surface Treatment Oil Impregnant Density 7.0g/cm3;-7.4G/Cm3; Tensile Strength 1100MPa Yield Strength 430MPa Transport Package PE Bag, Bubble Bag, Carton, Pallet Specification Suited size carton Trademark HLXCL Origin China HS Code 8409999100 Production Capacity 600000/YearProduct Description

Manufacturing motorcycle spare parts high precision sprocket by powder metallurgy| Product Name | Sintered parts by powder metallurgy |

| Material | Iron powder, alloy powder,precious metal powder |

| Technology | Sintering - Powder Metallurgy |

| Certificate | ISO9001/TS16949 |

| Surface Treatment | High frequency quenching, oil impregnation,CNC,vacuum cleaning,polishing, |

| Apperance | No crumbling, cracks, exfoliation, voids, metal pitting and other defects |

| Process Flow | Powder mixing - Forming - Sintering - Oil impregnation - Sizing -Ultrasonic cleaning - Steam oxidation - Oil impregnation - Final inspection - Packing |

| Application | Motorcycle parts, auto parts, Power Tools parts, Motor parts, electric Bicycle, |

Production process of powder metallurgy:

Powder mixing - Forming - Sintering - Oil impregnation - Sizing -Ultrasonic cleaning - Steam oxidation - Oil impregnation - Final inspection - Packing

Company profile

JINGSHI established in 2007

Manufacturer & Exporter

Exacting in producing powder metallurgy gears and parts

Passed ISO/TS16949 Quality Certificate

Advanced Equipment

Numbers senior R & D engineers and Skilled operators

Precise Examination Instruments.

Strict Quality Control

With the "More diversity, More superior, More professional " business purposes, we are committed to establish long-term friendship and win-win relationship with domestic and international customers to create a bright future .

Certification

JUST SEND YOUR 2D OR 3D DRAWING OF THE PARTS!