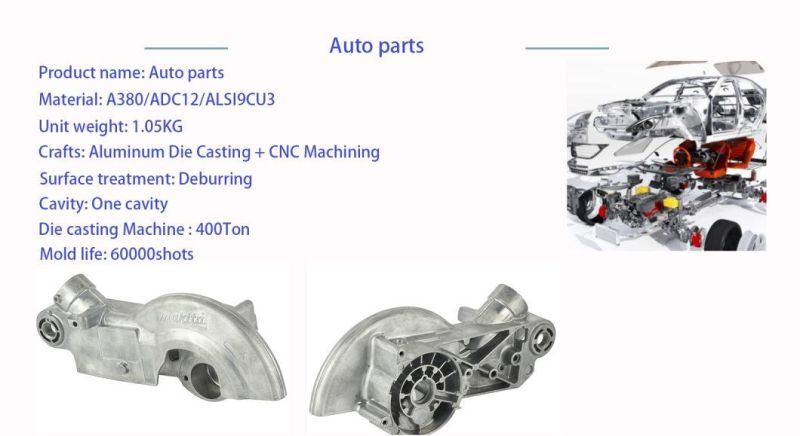

Custom Aluminum Zinc Shot Blasting Diecast Motorcycles Engine Cover Parts

Ningbo Aikehan Metal Product Co., Ltd.- Warranty:Online Technical Support

- Type:Motorcycle Engine Assembly

Base Info

- Start:Custom Made

- Cylinder NO.:Custom Made

- Stroke:Custom Made

- Cold Style:Custom Made

- Energy Transformation:Custom Made

- Certification:ISO9001:2000

- Thermal Machine:Custom Made

- Four Stroke Principle:Custom Made

- Main Market:North America

- Surface Tolrance:0.1-0.2

- Surface Roughness:Ra1.6-3.2

- Design Software:Solidworks,Proe,Flowing

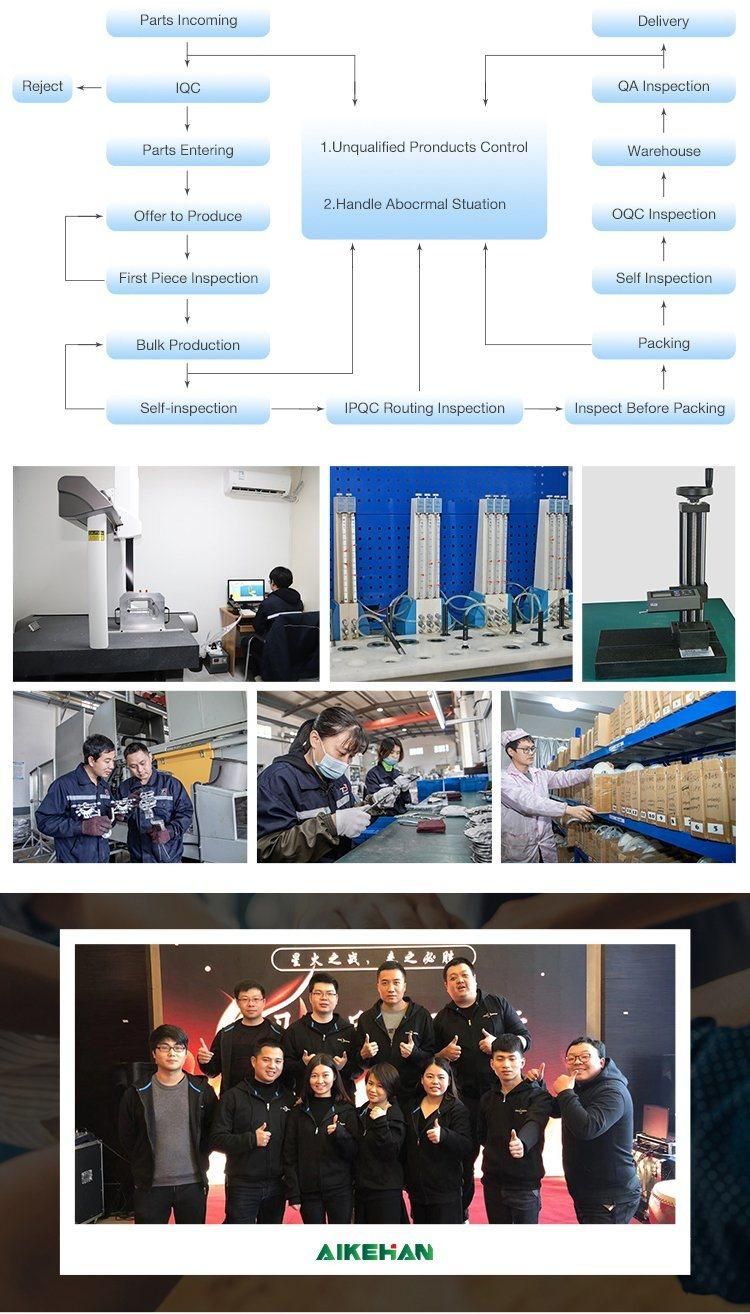

- Inspecification:100%Before Packing

- Mold Life:100000shots

- Mold Lead Time:40-60days

- Cavity Material:Fsh13

- General Draft Angle:1.5degree.OEM

- Die Structure:Moving Die, Fixed Die

- Transport Package:Carton, Wood Box, OEM

- Specification:oem

- Origin:China

- HS Code:7616999000

- Production Capacity:50000,Month

- Package size per unit product:35.00cm * 23.00cm * 22.00cm

- Gross weight per unit product:5.300kg

Description

Aluminum die cast process is a process in which the molten liquid of aluminum alloy is poured into the mold and solidified into a casting under the action of pressure.

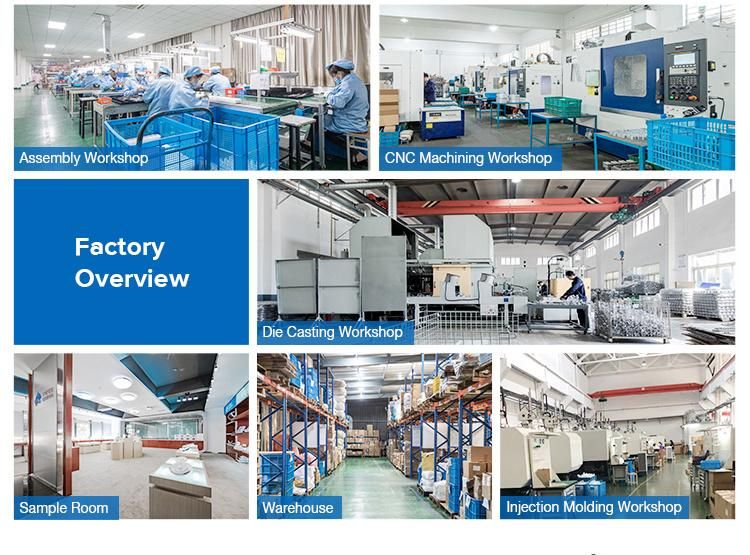

Our factory has 180-1260 tons of cold die casting machine, which adopts high-pressure casting. The product produced by us not only have high surface tolerance grade, good roughness and high strength, but also have high productivity,at least 50000 pcs per month,and our product scrap rate is controlled within 2%. At the same time, we are also equipped with a CMM to detect and control the product tolerance and size within the range of customer requirements,and it's toelrance is 0.0005.We also provide assembly service if customers requires.

Development example:

Product pictures showing:

FAQ

FAQQ1. Can I have a sample order for Die casting product?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A:Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than.

Q3. Do you have any MOQ limit for Die casting product order?

A: Low MOQ, 1pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional.

Q5. How to proceed an order for Die casting product?

A: Firstly let us know your requirements or application. Secondly We quote according to your requirements or our suggestions. Thirdly customer confirms the samples and places deposit for formal order. Fourthly We arrange the production.

Q6. Is it OK to print my logo on Die casting product?

A: Yes. Please inform us formally before our production and confirm the design firstly based on our sample.

Q7: Do you offer guarantee for the products?

A: Yes, we offer 2-5 years warranty to our products.

Q8: How to deal with the faulty?

A: Firstly, Our products are produced in strict quality control system and the defective rate will be less than 0.2%. Secondly, during the guarantee period, we will send new lights with new order for small quantity. For defective batch products, we will repair them and resend them to you or we can discuss the solution i ncluding re-call according to real situation.